EV Supply Chain > HV/LV Electrical Systems

EV HV/LV Electrical Overview

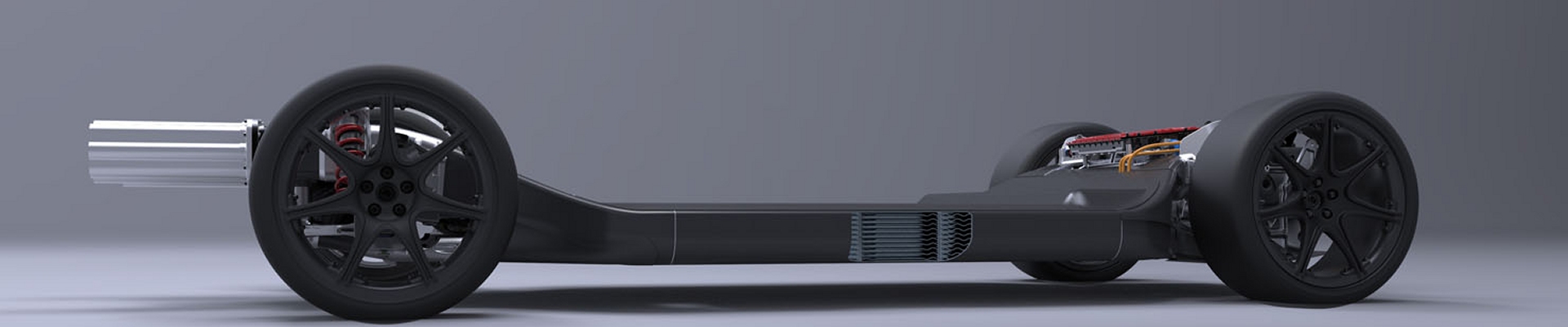

The HV/LV electrical system describes the power-distribution backbone of an electric vehicle: how energy flows from the traction battery through high-voltage (HV) components into the motor or e-axle, DC fast-charging interface, on-board charger (OBC), and how it is stepped down into low-voltage (LV) domains that run controls, safety, ADAS, connectivity, and comfort systems.

Position in the EV Stack and Supply Chain

- Upstream: Battery packs/modules, motors/e-axles, power-electronics modules, high-voltage components, semiconductors (SiC / IGBT / GaN).

- --> HV/LV systems: Power conversion (inverter, DC-DC, OBC), distribution, protection, and vehicle-level control units.

- Downstream: Propulsion, ADAS/AV compute, body/zonal systems, thermal loops, charging interfaces, V2X functions.

| Domain | Typical Voltage | Primary Role | Key Components |

|---|---|---|---|

| High-voltage (HV) | 400-800 V DC (and higher on next-gen platforms) | Traction power, DC fast charging, high-power auxiliaries | HV battery, contactors, busbars, traction inverters, OBC, HV DC-DC, DCFC interface |

| Low-voltage (LV) | 12 V / 24 V / 48 V | Controls, safety, sensing, communications, comfort | LV battery, PDUs, VCUs, zonal / domain controllers, actuators, infotainment, telematics |

High-Voltage (HV) System

The HV domain carries the bulk of traction and charging power. It is defined by safety, insulation, creepage and clearance, and the ability to handle high currents and switching events without undue losses or EMI issues. HV architectures are either 400 VDC or 800 VDC for newer platforms.

- HV battery pack, main contactors, pre-charge circuits, isolation monitoring.

- HV distribution: busbars, fuses, connectors, junction boxes, service disconnects.

- Traction inverters feeding one or more motors or e-axles.

- On-board charger (OBC) for AC input conversion to HV DC.

- HV DC-DC converters stepping HV down to LV domains.

- Fast-charging interfaces and associated HV protections.

Key engineering themes in the HV domain include thermal behavior, switching losses and efficiency, EMC/EMI compliance, creepage/clearance, insulation coordination, and robust fault detection under both drive and charging conditions.

Low-Voltage (LV) System

The LV domain supports vehicle control, safety, sensing, communications, and comfort. It also powers high-performance compute for ADAS and autonomy, either directly or via intermediate rails. Traditional 12 V architectures are gradually giving way to 24 V and 48 V systems on advanced platforms.

- LV battery and LV power distribution units (PDUs) or fuse/relay/solid-state power boxes.

- Vehicle control units (VCUs), chassis and body controllers, zonal and domain controllers.

- Safety-critical actuators such as braking and steering systems, as well as pumps, valves, and fans.

- Lighting, HVAC actuators, infotainment, telematics, and connected-vehicle systems.

- Redundant LV power paths for systems that must remain operational under faults and brownouts.

Designing a robust LV domain requires maintaining stable supply rails under dynamic load conditions, separating critical from non-critical loads, and supporting future growth in compute and sensor power without excessive harness complexity or weight.

Advanced Chassis Actuators

Modern EVs increasingly rely on LV-powered chassis actuators that extend far beyond traditional steering or damping functions. High-authority systems such as active suspension, torque-vectoring axle actuators, rear-wheel steering (4WS), steer-by-wire, crabwalk mechanisms, and active aero surfaces all draw from 12 V, 24 V, or 48 V LV rails and are orchestrated by zonal controllers or dedicated chassis control units.

These actuators combine electric motors, electro-hydraulic modules, high-resolution position sensors, and rapid closed-loop controllers to shape vehicle dynamics, stability, comfort, and maneuverability. While they operate electrically within the LV domain, they consume data from propulsion, braking, and in some cases ADAS road-preview systems, making them tightly integrated into the broader vehicle-control architecture.

Key Subsystems/Assemblies

Battery Management System (BMS / BCU)

- Supervises all HV safety functions: isolation monitoring, contactors, current limits, safe shutdown.

- Performs state-of-charge (SOC) and state-of-health (SOH) estimation, cell balancing, and diagnostics.

- BCU (Battery Control Unit) often refers to the pack-level or module-level controller; functionally part of the BMS.

- Interfaces tightly with the VCU, inverter, charger, and thermal systems through the HV/LV electrical architecture.

DC-AC Traction Inverter

- Converts DC from the battery into three-phase AC for one or more traction motors.

- Uses SiC MOSFETs or IGBTs, with SiC increasingly favored for higher-voltage and high-power applications.

- Directly influences efficiency, performance, and thermal requirements, especially for high-duty-cycle fleets.

DC-DC Converters

- Step HV buses down to LV rails (12V / 24V / 48V), sometimes with multiple isolated outputs.

- Provide stable LV power during transient events, including fast charging, aggressive regenerative braking, and compute load swings.

- Enable elimination of belt-driven mechanical accessories inherited from ICE architectures.

On-Board Charger (OBC)

- Converts AC grid or depot power into HV DC for the battery pack.

- Implements power-factor correction, isolation, and communication with external EVSE.

- Frequently integrated with DC-DC converters and sometimes with the traction inverter into a unified power control unit (PCU).

- GaN devices are emerging in OBC stages to enable higher switching frequencies and more compact magnetics.

Power Control Unit (PCU) and Motor Control

- Integrates inverter(s), DC-DC converter, and sometimes OBC into one assembly near the motor or e-axle.

- Hosts many of the highest-value power semiconductors in the vehicle and co-locates them for thermal and packaging efficiency.

- May include dedicated motor control logic (MCU) or share control with the VCU.

HV and LV Distribution

- HV side: busbars, cables, HV junction boxes, service disconnects, and HV connectors that must meet stringent insulation and creepage requirements.

- LV side: PDUs, fuse/relay boxes, solid-state power controllers, and zonal distribution harnesses.

- Requires careful coordination of safety, manufacturability, weight, routing, and serviceability.

Power Electronics Devices (SiC, GaN, IGBT)

The HV/LV electrical stack is where most high-value power-semiconductor devices are deployed, bridging upstream device supply chains and downstream vehicle platforms.

| Device Type | Typical Use | Advantages | Tradeoffs |

|---|---|---|---|

| SiC MOSFET | Traction inverters, HV DC-DC, DC fast-charging stages | High efficiency, high voltage and temperature capability, smaller cooling requirements | Higher device cost, evolving substrate and wafer supply base |

| IGBT / Si MOSFET | Cost-sensitive inverters, mid-power converters, legacy platforms | Mature, lower device cost, widely available tooling | Higher switching losses and lower efficiency at higher voltages and switching frequencies |

| GaN Device | On-board chargers, LV converters, high-frequency stages | Very high switching speed, compact magnetics, high power density | Automotive ecosystem still maturing; packaging and cost considerations |

Controllers

Control units orchestrate both HV and LV systems, consolidating functions and enabling software-defined vehicles..

- VCU (Vehicle Control Unit): Central intelligence for propulsion, torque management, regenerative braking, and safety interlocks.

- PCU/MCU (Power / Motor Control): Manages inverter operation, motor torque and speed, and associated protections.

- BCM (Body Control Module): Legacy LV controller for body functions; in modern platforms, functions migrate into zonal controllers.

- Gateway ECU: Bridges CAN, LIN, Ethernet, and other networks; enforces cybersecurity, firewalling, and OTA pathways.

- Zonal Controllers: Next-generation LV architecture nodes that consolidate multiple ECUs per zone, reducing harness length and complexity.

Interfaces with Other EV Systems

- Battery supply chain and BMS: Defines pack voltage, current limits, thermal constraints, and safety envelopes that the HV / LV stack must respect.

- Motors and drivetrains: Inverters and e-axles are co-designed for efficiency, torque delivery, and thermal behavior across drive cycles.

- ADAS and autonomy: HV / LV architecture must support high-power compute, redundant sensor power, and low-noise rails for cameras, radar, lidar, and sensor-fusion systems.

- Charging and infrastructure: HV / LV stack connects the vehicle to depot charging, public DC fast charging, and vehicle-to-grid (V2G) or vehicle-to-depot (V2D) power flows.

- Thermal systems: Power electronics, battery, and motors often share cooling circuits, making electrical and thermal architectures tightly coupled.