EV Supply Chain > ADAS/AV Systems

ADAS/AV Stack Overview

This section describes the hardware and integration supply chain for Advanced Driver Assistance Systems (ADAS) and Autonomous Vehicle (AV) systems. It focuses on sensors, compute, controllers, networking, calibration, and downstream vehicle integration. The stack can be viewed in two dimensions: the core autonomy layers that enable safe self-driving, and the vehicle digital layers that provide connectivity, updates, and consumer experience. Software, cloud training, simulation, and OTA (Over-The-Air) model life cycles are covered on separate pages.

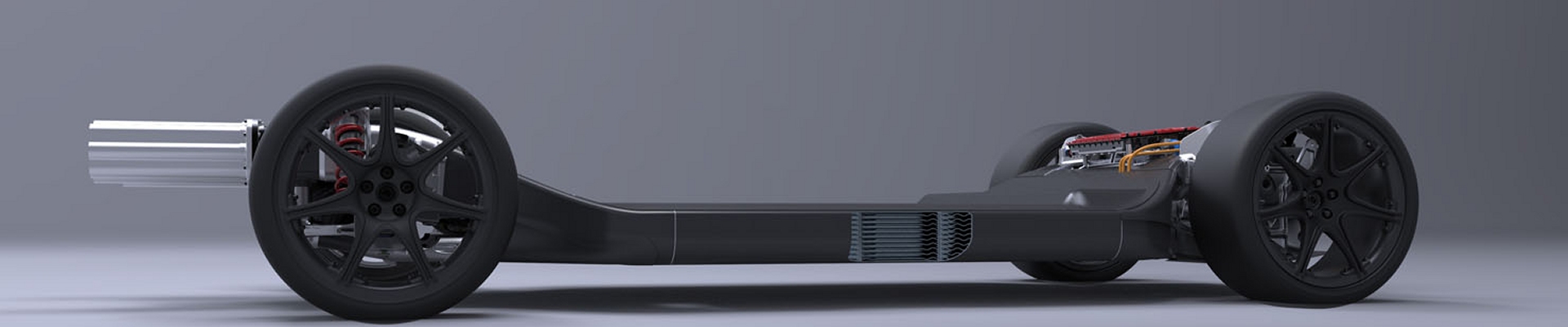

Position in the EV Architecture

- Upstream inputs: CMOS image sensors, radar RF chipsets, lidar emitters and receivers, MEMS IMUs, GNSS chipsets, advanced-node compute SoCs, optics, connectors, and harnessing.

- --> ADAS/AV hardware : Sensor modules, sensor fusion hardware, inference compute and autonomy domain controllers (DCUs), safety controllers, high-speed networking, calibration and mounting systems.

- Downstream consumers: Vehicle control units (VCUs), chassis controllers, LV electrical and thermal systems, and higher-level OTA and cloud platforms.

Supply Chain Flow

Upstream: Materials and Devices

- CMOS image sensors (CIS) for cameras.

- Radar transceivers and RF front-ends.

- Lidar emitters (VCSEL, diode, fiber) and receivers (APD/SPAD).

- MEMS IMUs and gyroscopes.

- GNSS chipsets and RF front-ends.

- Edge-AI compute SoCs, NPUs, and GPUs manufactured on advanced process nodes.

- Automotive-grade connectors, harnesses, optics, and enclosures.

Midstream: Modules and Subsystems

- Camera modules: sensor + lens + housing + heaters/cleaning elements.

- Radar modules: RF chipset + antenna-in-package + radome.

- Lidar modules: optical train + scanning mechanism + cleaning/defogging systems.

- IMU/GNSS modules: integrated positioning units.

- Autonomy DCUs and inference ECUs: boards, packaging, power stages, and cooling.

- Calibration rigs and alignment systems used during manufacturing and service.

Downstream: Integration and Validation

- LV power allocation from 12 V / 24 V / 48 V rails and protection design.

- Integration into in-vehicle networks (Ethernet, CAN-FD, SerDes camera links).

- Mechanical placement for field of view, overlap, and blind-spot reduction.

- End-of-line calibration and validation for sensors and DCUs.

- Environmental sealing, vibration isolation, and durability qualification.

Key Hardware Systems

Camera Systems

- Primary perception sensor for many OEMs.

- Supply chain includes CIS dies, lenses, filters, heaters, and housings.

- Integration challenges: thermal drift, contamination, glare, and vibration.

Radar Systems

- Short-range and long-range radar operating mainly around 77 GHz.

- Robust in rain, fog, and low visibility; strong at range and relative velocity measurement.

- Supply chain: RF CMOS, antenna-in-package (AiP), radomes, and calibration tools.

Lidar Systems

- Used selectively for high-resolution 3D geometry and redundancy.

- Supply-chain sensitivity around VCSEL emitters, detectors, optics, and scanning assemblies.

- Integration needs include cleaning, de-icing, heating, and aerodynamic placement.

Ultrasonic Sensors

- Low-cost, short-range sensing for parking and low-speed maneuvers.

- Simple transducers and modules, but heavily used in legacy and current platforms.

IMU/GNSS Modules

- Backbone for motion estimation and localization when combined with other sensors.

- Supply chain: low-drift MEMS IMUs and high-quality GNSS receivers and antennas.

Autonomy Compute and Domain Control Units (DCUs)

- Host perception, fusion, and planning workloads for ADAS and AV features.

- Built on advanced-node silicon with high TOPS-per-watt and automotive safety features.

- Integration requirements: stable LV power, significant cooling capacity, redundant networking, safety islands, secure boot, and hardware root of trust.

Networking, Power, and Integration

Networking and Data Backbone

- Automotive Ethernet (1-10 Gbps) for high-bandwidth sensor and fusion links.

- CAN-FD for safety-critical signaling and state management.

- LVDS / SerDes links for camera and some radar/lidar data paths.

- Strong coupling with gateways and zonal controllers in the LV electrical domain.

LV Power Requirements

- Sensors and DCUs draw from 12 V / 24 V / 48 V LV rails.

- LV power must be stable, low-noise, and designed with redundancy where required.

- High compute loads create LV transients and thermal loads that must be co-managed with HV/LV and thermal systems.

Thermal and Mechanical Integration

- DCUs and some lidars require liquid or forced-air cooling and robust thermal paths.

- Shared thermal loops with battery and motors must be co-optimized.

- Mechanical integration includes mounts, brackets, wiring routing, sealing, and vibration management.

Interfaces with Other Systems

HV/LV Electrical

- Provides LV power rails and the in-vehicle networks (Ethernet, CAN-FD, LIN) used by sensors and DCUs.

- ADAS / AV hardware must respect LV power budgets, EMI/EMC constraints, and thermal limits set by the broader electrical architecture.

Chassis and Actuation

- Autonomy and ADAS compute produce steering, braking, and torque commands.

- Physical execution occurs in steer-by-wire, brake-by-wire, torque-vectoring, and suspension systems documented in the Chassis / Vehicle Dynamics and HV/LV pillars.

Sensors and IoT Layer

- Some sensors (wheel speed, temperature, pressure, vibration) belong to a general Sensors and IoT layer and support many functions beyond ADAS/AV.

- ADAS/AV-specific sensors (camera, radar, lidar, driver monitoring) are covered here but cross-link to the broader Sensors and IoT pages where appropriate.

Connectivity and Telematics

- Vehicle connectivity (4G/5G, V2X, Wi-Fi, GNSS corrections) supports map distribution, telemetry, diagnostics, and some connected-driver assistance functions.

- While not part of the ADAS/AV hardware supply chain, these systems enable remote monitoring and fleet operations for autonomy programs.

AI Training & Simulation

ADAS/AV hardware depends on upstream AI training pipelines—large-scale video datasets, simulation engines, and GPU/TPU clusters—that produce the neural networks deployed onto in-vehicle inference compute. These software systems are covered in the Autonomy Model Lifecycle and OTA pages.

OTA Update Infrastructure

- Sensors and autonomy controllers receive firmware updates and configuration changes via OTA systems.

- This creates a direct dependency between the physical autonomy hardware and the OTA and cloud pillars that manage software and model lifecycle.

Middleware and Vehicle OS Layer

- Domain controllers run on RTOS, POSIX OS, or proprietary middleware that manages scheduling, isolation, and safety watchdogs.

- Although primarily software, these layers strongly influence how effectively ADAS/AV hardware resources are used.

Cybersecurity and Safety Governance

- Autonomy hardware must support secure boot, cryptographic roots of trust, intrusion detection, and secure communications.

- Cybersecurity and safety governance are documented in GRC and Cybersecurity pillars, but ADAS/AV hardware is a major enforcement point for these controls.

Supply Chain Bottlenecks

| Hardware Domain | Supply-Chain Sensitivity |

|---|---|

| Inference SoCs and AI Accelerators | Dependence on advanced-node fabs, limited vendor set, long qualification and migration cycles. |

| CMOS Cameras | Sensor shortages, packaging capacity limits, thermal and reliability constraints. |

| Lidar Modules | VCSEL supply, optical manufacturing complexity, calibration throughput and cost. |

| Radar | RF semiconductor capacity, antenna-in-package availability, regional spectrum rules. |

| Calibration and Test | Dependence on specialized tooling and skilled labor for alignment, calibration, and end-of-line test. |

| Module Integration | Tight coupling between OEMs and Tier 1s, regional certification needs, and long redesign cycles. |

Why This Stack Matters

- Determines the feasibility, performance, and safety ceiling of ADAS and AV features.

- One of the most supply-chain-constrained domains in modern EVs due to advanced-node silicon and complex sensor modules.

- Drives pull-through demand for semiconductors, optics, RF, calibration, and specialized manufacturing.

- Critical for fleet economics where autonomy can reduce labor cost, increase utilization, and change energy and charging patterns.